Know-how

Design

MONTEIRO Company has a design & methods office implementing:

- Classical studies for piping and metal work manufacturing

- And development of new process and operating procedures.

Piping and metal works design:

- Piping stress calculation ;

- Support calculation ;

- Tooling calculation (especially hydrostatic test) ;

- Vessel's calculation

- Isometrics ;

- Equipment plans ;

- Detailed plans of metal works parts ;

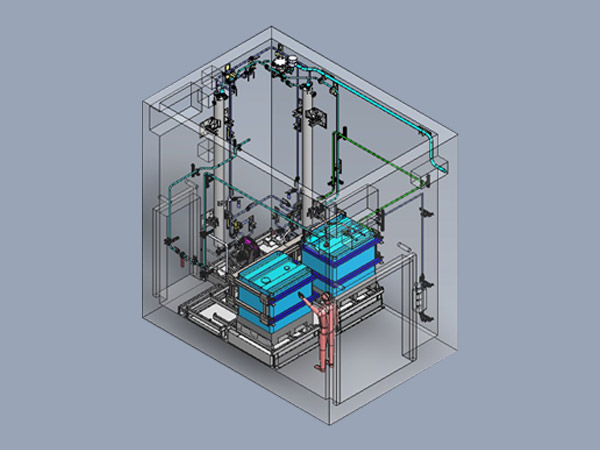

- 3D modelling

New process development: Innovative inerting process, tooling for freezing operation development, specific tooling for approaching before welding, handling …

Software: Pipestress, Caesar II, Autopipe Vessel, Mathcad, Nastran, Samcef, Ansys, Beamstress, Robot Structural Analysis, Autocad, Solidworks

Regulation, construction codes: RSE-M, RCC-M, CODAP, CODETI, NF EN 13480, NF EN 13445, EN 1090, DESP, ESPN

Preparing

Our "Welding Quality Assurance" division provides regulatory and normative assessment to address relevant technical solutions to the needs of our clients.

The equipment records files are created, verified and approved internally; then a comprehensive validation process is implemented including our customers and external inspection organisation when required

MONTEIRO Company brings its expertise on welding activities where a quality assurance survey is required in accordance with the following normative & regulatory requirements:

RCC-M / RSE-M / CODAP / CODETI/ NF EN 13480 / NF EN 13445 / NF EN 1090 / NF EN 287 / NF EN ISO 9606 / NF EN ISO 15614 / NF EN ISO 14732 / NF EN ISO 3834 / DIRECTIVE MACHINES / DESP / ESPN / REGLEMENTATION CPP-CSP / ARRETE INB

Manufacturing

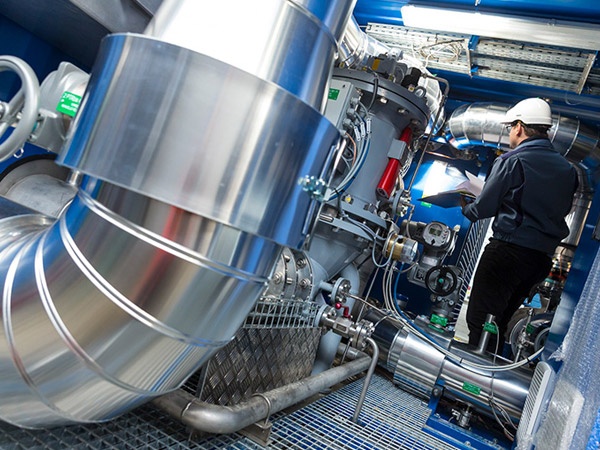

MONTEIRO Company owns manufacturing workshops that represent a total area 4500 m² equipped with overhead cranes with hook capacity reaching 5T.

Metal works manufacturing

Workshop manufacturing of pressure vessels dedicated to nuclear sector.

Components manufacturing

Re-manufacturing – retrofitting (equipment ex tubing – re-tubing).

Valve's double covers big diameters (DN250, 400, 600) meeting RCC-M requirements.

NDT's / tests: VT, DT, PT, UT, RT, hydrostatic and leak tests, etc. destructive tests

Manufacturing

Piping precasting

Supports, walkways, platforms and metal structure precasting

Hydrostatic test tooling

Design and manufacturing autonomous & instrumented skids

Inspection

DPT

Hydraulic tests

Operations

MONTEIRO Company operates on site for its clients for maintenance or new works operations.

Metal works

- Welding repairing on equipment

- Re-qualification of pressure vessels by hydrostatic test

- Installation and substitution of components on site (flange, tank cover, manholes…).

Piping

- Piping & supporting

- Maintenance works (Replacing all or part of piping, taps and supports).

- Production unit revamping

- Operation optimization without unit shutdown (freezing, tapping)

- Manual and orbital welding

- Mechanic shutter for hydrostatic test

- Extraction of foreign objects.

Project management

MONTEIRO Company takes over multidisciplinary projects from design to implementation.

- Project management;

- Design studies ;

- Coordination and conducting ;

- Management of sub-contractor activities (Electricity - system control, civil work, NDT's).

- NDT re-qualification

MONTEIRO Company has turned its experience into expertise, especially, by initiating a methods & design division that provides and offer customized solution to every situation.

We are capable to provide services in piping, steel works and welding sector and take over complete projects as well.

Our organization allows us a high responsiveness in managing a turnkey project from design, when needed, from compiling the business package to site operation. This is the ability recognized by our customers to commit ourselves in management of unforeseen activities in addition to daily business.