Achievements

Design

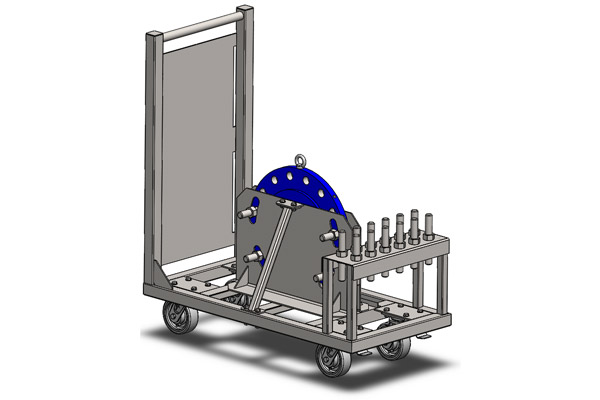

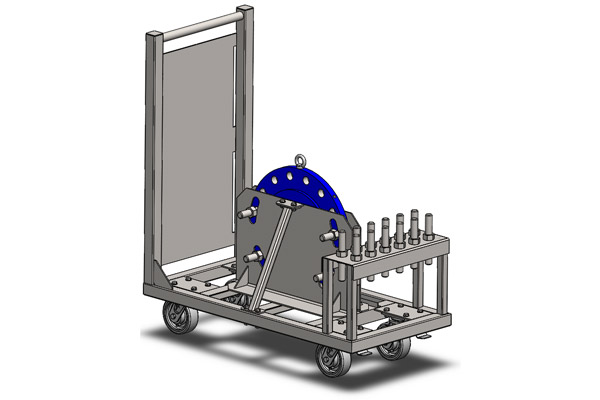

Tooling manufacturing

Design & manufacturing of maintenance activities tooling

Application: Nuclear power plants

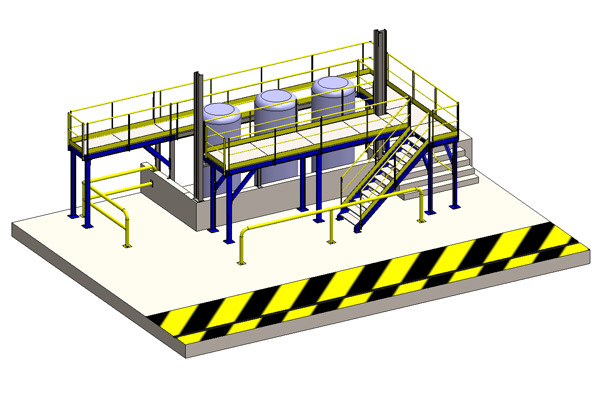

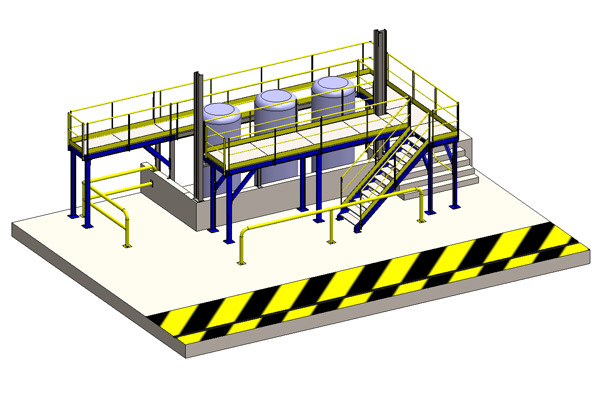

Design and installation of a walkway

Mapping on site, General design (definition plans & calculation), metallic structure manufacturing, positioning and assembly of the different modules of the structure.

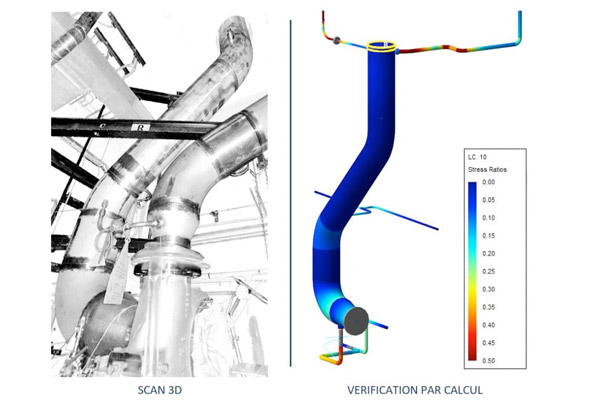

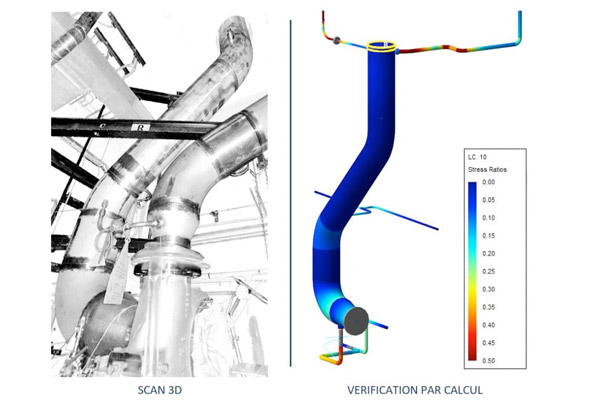

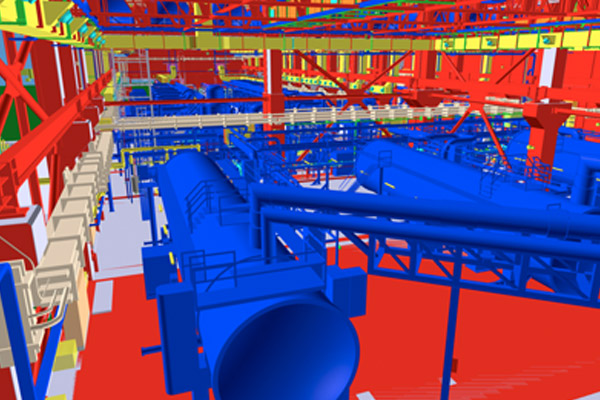

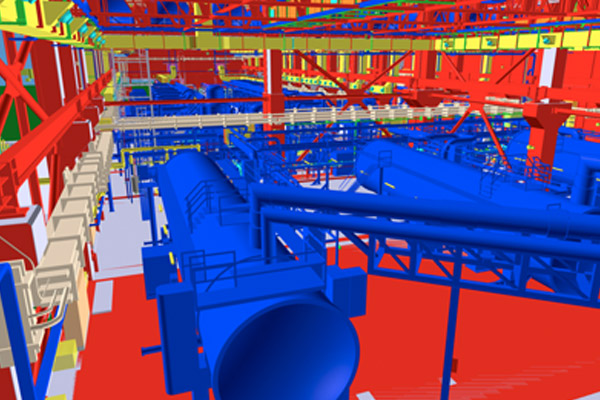

3D mapping on site

As on site points cloud integration, Creation, integration and design.

Manufacturing

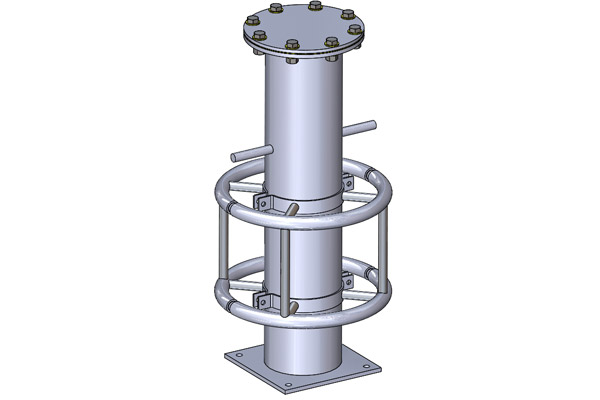

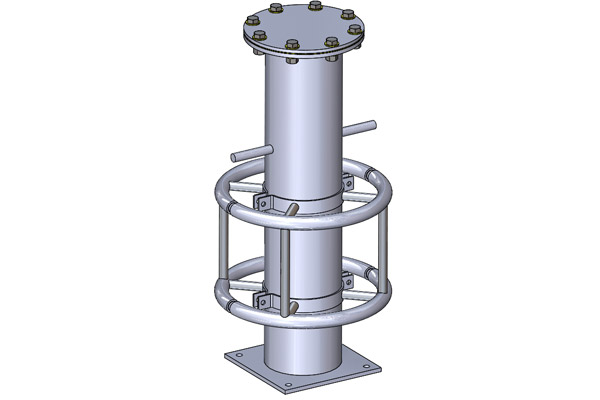

Collectors manufacturing

Manufacturing aluminum collectors, baskets, crinoline in the frame of the nuclear program for used coal processing.

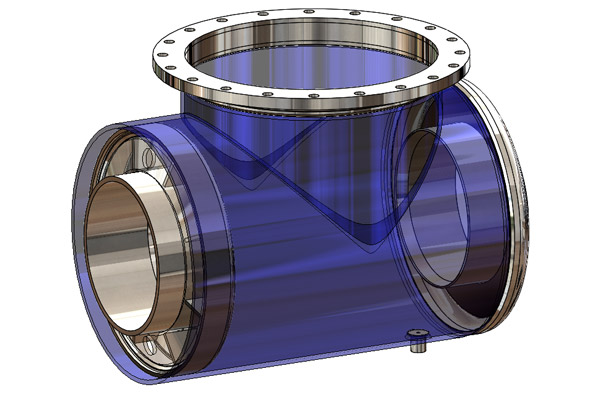

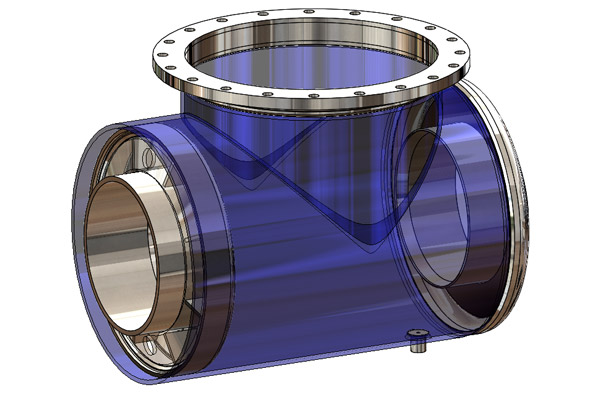

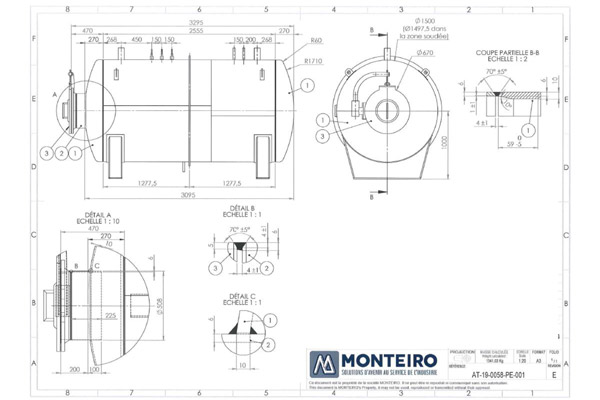

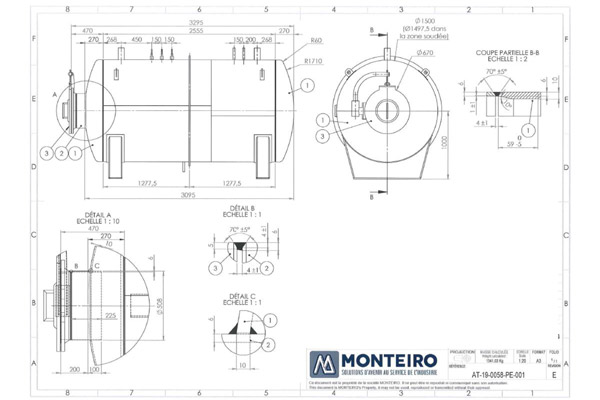

Manufacturing of valves covers

Valves cover manufacturing according to RCC-M level 2. Export product

Intervention

Maintenance operation, welding and inspection in nuclear power plant

Maintenance intervention in French nuclear power plants for welding, piping and metal works operations.

CPP/CSP system components replacement

Replacement of taps, valves, piping sections according to RCC-M level 1 and 2.

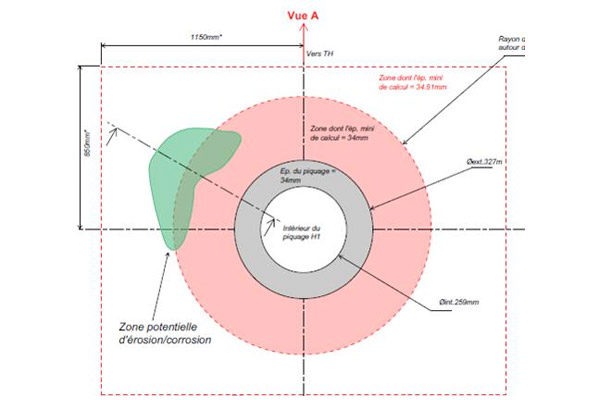

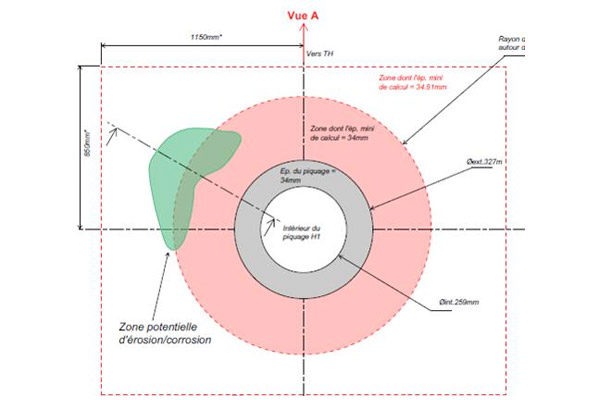

Weld dressing on pressure vessel

Visual, DPT and US inspection.

repairing by digging and weld dressing the thickness loss on the cover of a vessel and the purging connections.

Managing projects

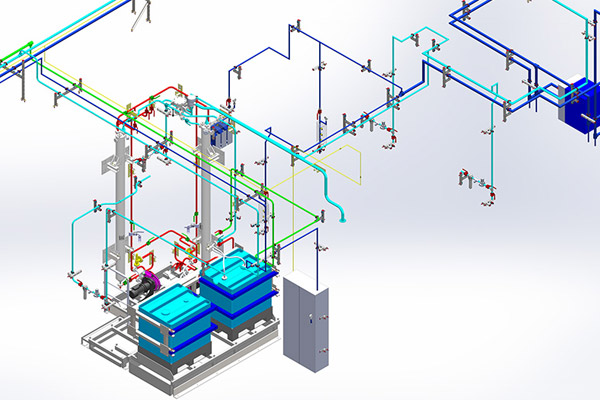

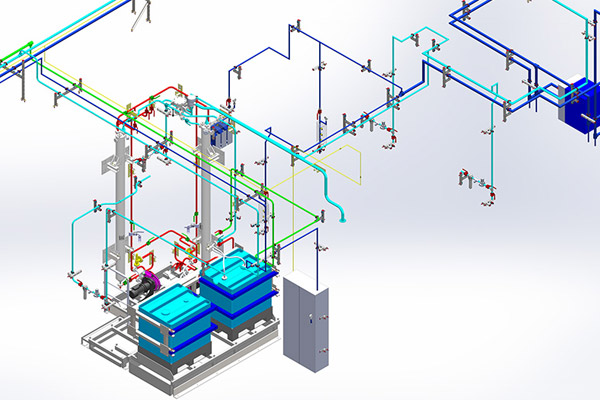

Creation of a radioactive waste processing unit - piping

Creation of a new processing unit for solid radioactive waste (10 200m² total area).

Operation scope Design, manufacturing & Installation of all the piping networks.

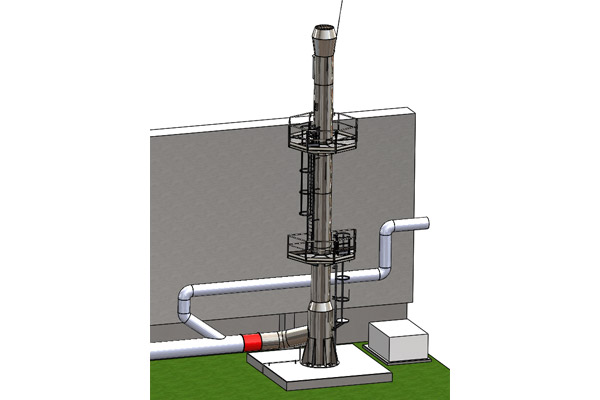

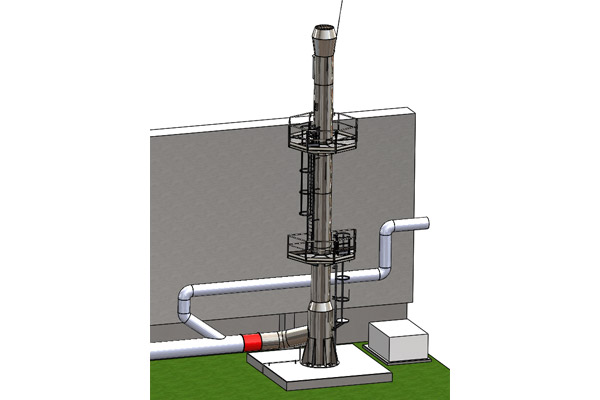

TRIDENT project - Lot 2 exhaust duct

creation of a radioactive waste processing unit - Exhaust ductée

Design, manufacturing and installation of a 19-meter ventilation exhaust duct

National change campaign for pressurized vessels for Nuclear industry level 3

Deployment at national scale (CPY level) technical solution, developed by our design department, for tank bottom substitution (Pressurized nuclear equipment level 3).

TER - ITER project

Manufacturing & assembly of piping networks for ITER project.